At Pyper, we learn and grow together.

We believe in fairness, honesty, and good people. Forge your new career path with us.

Small-shop feel with big opportunities.

Solid foundations.

We’re focused on the essential skills that produce great work across the team — from apprentice to president.

Intentionally creative.

New ideas require novel approaches and mindsets. We know there’s always something new to discover.

Our Mission: To provide exceptional American made dies & custom automation using foundational skill, intentional creativity and proven technology while fostering communication and teamwork.

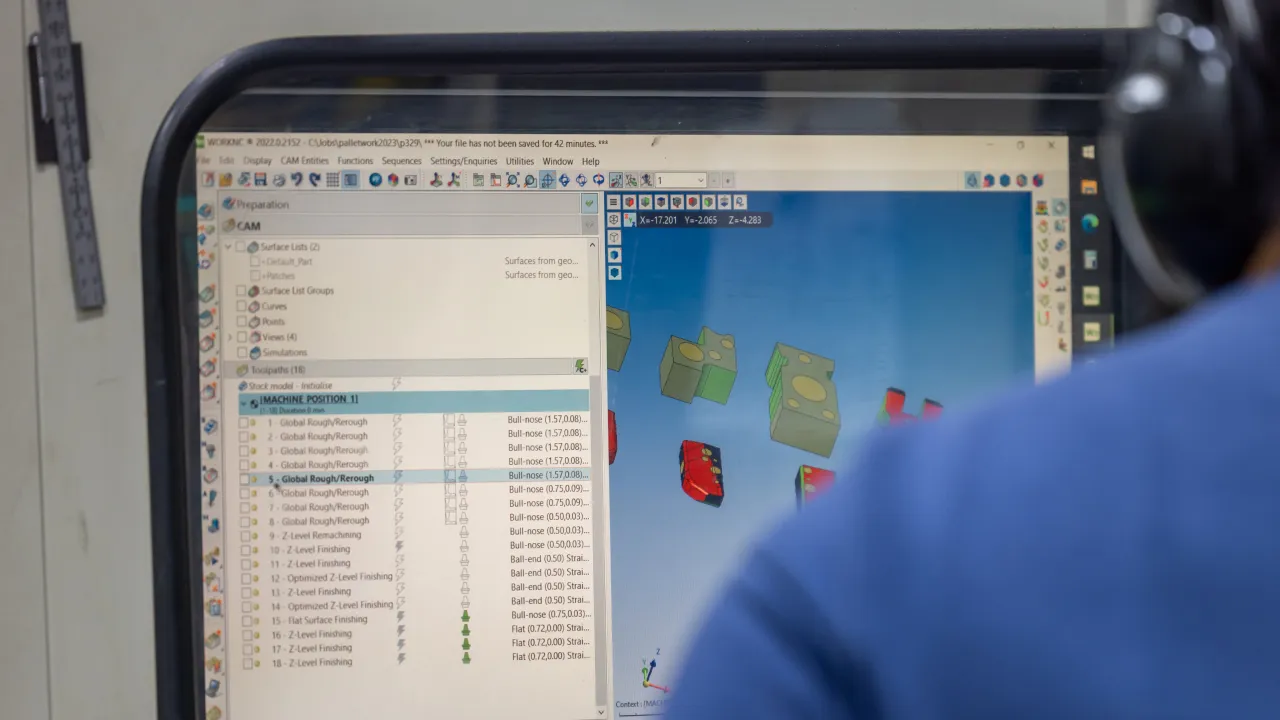

Proven experts.

At Pyper, you’ll work with some of the industry’s best—working to produce exceptional American-made dies and custom automation.

Collaborative, always.

Communication and teamwork are the bedrock of Pyper’s culture. We work with each other to create excellent outcomes.

What’s the best part of working at Pyper?

Here’s what our team said.

Dave Miller

CNC Operator

Matt Hallock

CNC Programmer

Jon Buhland

Machinist

Chris Roossinck

Die Builder

Theresa Kelly

Project/Purchasing Manager

David Stobert

Automation Mechanical Design

Brian Popma

Lead Builder

John Pyper

President/Owner

Discover your path to a fulfilling career.

Pyper Tool works in conjunction with Grand Rapids Community College (GRCC) to provide U.S. Department of Labor registered apprenticeship programs in Tool & Die, CNC Machinist and General Labor.

This 4 year program is a combination of work experience and classroom training. We assist with tuition reimbursement (100% with proof of completion with a grade of B or better and 50% with a grade of C) through the help of the Michigan Apprenticeship Program Plus (MAP+) Grant funds.

Upon successful completion, our apprentices will have earned their Journeyman card.

1979 • Founding

Always wanting to own a business, John E. Pyper used his $8000 in retirement money to purchase equipment and founded Pyper Tool & Engineering in the back of a radiator shop in Comstock Park, MI.

1980 • Growing Roots

By 1980, a customer sold him a building and he had 6 people working with him to grow the business.

1995 • More Space

As Pyper grew, adding onto the existing building for the fourth time was not the answer. The building Pyper uses today was established to improve workflow.

2000–2003 • Efficiency

The “standard lifter” concept was developed through the efforts of the general manager, die makers, machinists and die designers to improve efficiencies and save time and money.

2007 • The Next Generation

In February of 2007, John’s sons Jeffery and John K bought Pyper Tool & Engineering and his son Joel took ownership of the standard lifter business.

2010 • Evolution

Having survived the 2007–08 automotive collapse, Pyper emerged stronger with additional customers and a new sales force, unlike many who fell into bankruptcy.

2016 • Investment

Pyper invested in an Aida DSF-N2-3000, 300 ton Servo Press to better serve its customers in search of progressive dies.

2022 • Leadership Change

Jeff retired in 2022, selling his portion of the business to John K.

2023 • Bright Future

We have BIG plans for Pyper Tool & Engineering, Inc. 2023 is the year of building great things on a strong foundation with creativity & great people.

Build your career with us.

Do you enjoy the challenge of technology? Do you have the stamina to work hard for a better future?